In recent years, with the promulgation and implementation of new energy efficiency standards in the motor industry, high-efficiency motors have attracted more and more attention in the water pump market, especially in municipal water supply and commercial building applications. IE5 motors have been favored by many users for their excellent performance and efficiency. As far as the water pump industry is concerned, in addition to several traditional motor manufacturers launching their own IE5 series motors, leading water pump manufacturers are also combining their own advantages to release IE5 motors to better adapt to water pump products. To this end, the Pump Friends Circle has compiled IE5 motor products launched by several water pump and motor manufacturers, so that everyone can get a glimpse of the appearance of mainstream IE5 motors.

Integrated motor solutions that combine connectivity, performance, energy efficiency, extensive connectivity, ease of operation and sustainability

hydrovar® X is one of the world’s leading water technology companies, committed to solving tough water and infrastructure challenges through innovation. By providing intelligent, cutting-edge technologies, reducing energy consumption levels and improving sustainability. One thing Xylem has in common with the greatest engineering innovators is continuous investment in new products, which is reflected in efficient solutions.

Product highlights:

Sustainability

The hydrovar® X uses IE5 reluctance-assisted motor technology. As a green technology solution, it demonstrates extraordinary energy efficiency while combining excellent performance and sustainability. Its uniqueness lies in the fact that it does not use rare earth metals, minimizing the impact on the environment and effectively addressing the dual challenges of resource utilization and environmental protection.

Easy to operate

The hydrovar® X is simple to use, precise and rugged, and can easily perform a variety of applications from common to demanding. The built-in application software is intuitively designed to facilitate commissioning, programming and daily operation, and supports full configuration of the pump. In addition, users can remotely control and manage the pump through the Xylem X application.

Intelligent pumping, precise and efficient

hydrovar® X is a pumping system that is designed with precision and performance in mind. Integrated protection functions effectively protect the safety of pumps and motors while improving the quality of grid energy. Factory preset multi-pump control (up to 8 units), Modbus and BACnet communication protocols as standard, make intelligent pumping within reach.

Compact design, flexible space

The hydrovar® X motor is exquisitely designed, occupies a smaller area, has a larger and more user-friendly interface, and is highly integrated. It can realize dynamic control at the best working point at any time. The onboard Internet of Things makes it easy for users to install, operate and realize agile monitoring connections. In addition, its flexible spare parts management can minimize inventory.

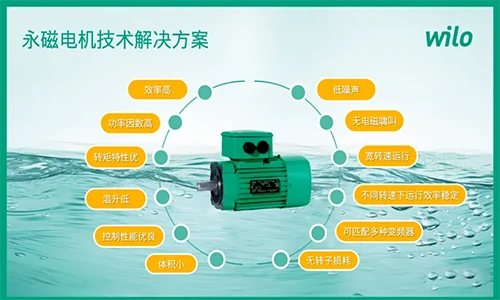

Wilo permanent magnet motor technology solutions

Wilo permanent magnet motors meet GB30253-1 energy efficiency standards and are suitable for a variety of pump types. They will become a powerful tool for energy conservation and emission reduction.

By optimizing the electromagnetic design, using high magnetic performance materials and precise control strategies, extremely high power density and efficiency are achieved. Wilo’s high-quality water pumps have significantly improved energy efficiency with the support of permanent magnet motors. When used at reduced frequency, the product efficiency is higher than Asynchronous motor products.

The use of permanent magnet motors also reduces maintenance costs and provides solid technical support for the green and intelligent water supply system. As a cutting-edge technology in the field of energy conservation and emission reduction, with its highest standard of energy efficiency performance, permanent magnet motor technology solutions are not only suitable for a variety of pump types, but also suitable for a variety of mainstream brands of inverter drives. It can also significantly reduce energy consumption and help Accelerate the realization of dual carbon goals.

Grundfos MGE motor

Grundfos MGE motor is a high-efficiency pump motor with an integrated design of frequency converter and permanent magnet synchronous motor. The entire series complies with IEC60034-30-2 IE5 level and IEC61800-9-2 IES2 level, and is one of the high-efficiency pump solutions currently available on the market.

The permanent magnet synchronous motor (PMSM) inside the MGE is optimized for the integration of the inverter. The compact size and IP55 protection level of the whole series greatly optimize the installation time and cost. In addition, the MGE is optimized for water pump applications and high local load efficiency. The built-in inverter of the MGE is designed for water pump load applications. Its functions include energy-saving operation, process control, low-noise operation, built-in various motor protections, and control and protection functions dedicated to water pumps, such as dry-running protection, reducing water hammer effect, etc.

High efficiency is the characteristic of Grundfos pumps and the focus of MGE motors. We meet and exceed the IE5 energy efficiency requirements.

Taking the MGE 11.0 kW 3×380-500V medium-speed motor as an example, at 380V/2600rpm, the motor efficiency is as high as 95.7%, 2.5 percentage points higher than the IE5 energy efficiency. After adding inverter control, the system efficiency can still maintain a level higher than IE5.

Compared with traditional asynchronous motors, MGE motors have significant advantages, mainly reflected in:

- Ultra-high energy efficiency, in line with and exceeding IE5 standards

- IP55 high protection level, on-site installation, no control cabinet required, frequency conversion motor integrated design perfectly matches all types of Grundfos pumps, and optimizes solutions in terms of installation, commissioning, operation, maintenance, etc.

- The system energy-saving control and algorithm optimization specially designed for water pumps can achieve a maximum system energy saving of up to 75%. Grundfos’ MGE motors are currently widely used in various water pumps, including multi-stage pump series CRE, CME, MTRE, single-stage pump series TPE, NBE, NKE and booster systems that meet various application purposes.

Dongfang Pump Industry YE5-80~355 series motor

Under the national strategic requirements of “carbon neutrality and carbon peak”, users have put forward higher requirements for motor energy efficiency. Based on the complete system established by our company for motor research and development, manufacturing, and quality process management over the years, we have launched the YE5-80~355 series of low-voltage and high-efficiency three-phase asynchronous motors. The YE5 series motor is a three-phase asynchronous motor with the highest efficiency and a high-end product of three-phase asynchronous motors. It can be widely used in various transmission machinery industries such as water pumps, fans, and plastic machinery. The excellent product performance of the motor creates greater value for users.

YE5 series motors have the following advantages:

- High efficiency: The efficiency of the YE5 series motors meets the Level 1 energy efficiency standard of “GB18613-2020 Electric Motor Energy Efficiency Limits and Energy Efficiency Grades”. The efficiency improvement compared to the YE3 motor is 1.4-7%, and the efficiency improvement compared to the YE4 motor is 0.4-3.6%. The efficiency improvement of small-power specifications is slightly greater.

- Standardized installation dimensions: This series of motors adopts a design with enlarged stator outer diameter dimensions. The motor housing structure is more novel and beautiful, and the heat dissipation effect is better. However, the installation dimensions are exactly the same as those of the Y2 and YE3 series, which allows users to directly replace the original obsolete products.

- Low noise: The motor design and manufacturing process adopts mature and proven new technologies, new materials and new processes, optimizes the winding design, adopts sinusoidal winding, optimizes the slot matching design, increases the stator and rotor air gap, etc., effectively weakening the harmonic magnetic field and reducing the motor stray loss and electromagnetic noise; the new fan structure design is used to enhance the ventilation and heat dissipation effect of the motor, reduce mechanical losses, and also reduce mechanical wind noise.

Leo Pump IPM5 permanent magnet synchronous motor

LEO’s self-developed integrated IPM5 permanent magnet synchronous motor system: a permanent magnet motor with super IE5 energy efficiency, which is far more efficient than IE5. Especially at low load, the IPM5 permanent magnet motor has higher efficiency than ordinary asynchronous motors, which can effectively reduce operating costs, save energy efficiently, and be environmentally friendly.

The water pump products equipped with this type of motor series not only reduce the operating noise comprehensively, but also greatly improve the operating energy efficiency (especially under low load conditions). Taking the 11kW product as an example, the IPM5 permanent magnet motor can save 4,500 kWh of electricity and reduce more than 3.5 tons of carbon emissions compared to ordinary motors in one year.

As a smart series product, Leo IPM5 permanent magnet smart series water pumps have achieved the goal of replacing a system with one product. It has powerful functions such as intelligent sleep and wake-up, multi-pump connection, etc. The sensors that match it can achieve multiple modes including intelligent constant pressure, constant pressure difference, constant temperature, constant temperature difference, etc., abandoning the complex external control system, so that customers can enjoy efficient and comfortable water delivery experience.

INNOMOTICS 1LE8005 electric motor

INNOMOTICS 1LE8005 national standard first-level energy-efficiency low-voltage three-phase asynchronous motor has the advantages of ultra-high energy efficiency and extremely high reliability. It can meet the high energy efficiency requirements of motors in different industries. It can be used in applications such as fans, pumps, compressors, extruders, as well as water treatment, buildings, papermaking, mining and other industries. Customized solutions can be provided according to customer special needs.

INNOMOTICS 1LE8005 has the following features:

- Higher energy efficiency: more energy-saving, efficiency meets the national standard first-level energy efficiency

- More compact: more compact structural design, saving space

- Lower temperature rise: ensure worry-free operation of windings and bearings

- Wider voltage: wider variable frequency operation voltage range

- Longer warranty: better quality, bringing longer standard warranty period

- Shorter delivery time: shorter delivery time

- More flexible: more options, more flexible configuration

- More cost-effective: shorter investment return cycle

ABB M2QA IE5 motor

Economical, durable, efficient and reliable

As a classic product of ABB, the M2QA series motors are characterized by high efficiency, reliability, economy and durability, and have been favored and praised by customers from all walks of life for more than 20 years. With its ultra-high energy efficiency, more reliable structural design, more excellent insulation system, lower temperature rise and excellent customization capabilities, it can be widely used in papermaking, lifting, metallurgy, power, shipbuilding, textile, food and beverage, mining, cement and other industries.

Optimization plan

Energy Saving and Efficiency In the process of R&D iteration of M2QA IE5, the latest concepts of motor design and big data analysis technology were combined. Through a more optimized electromagnetic solution, it not only achieved a leap-forward improvement in motor energy efficiency, but also significantly reduced energy consumption. consumption and carbon emissions, significantly shortening the investment return cycle.

WEG IE5 motors

In the rapid development of industrial technology, IE5 motors are leading the innovation of motor technology with their excellent performance and environmental protection characteristics. IE5 motors not only represent the forefront of technology, but also deeply reflect the concept of sustainable development.

With its profound technical accumulation, WEG has launched the W21 IE5 series asynchronous motors (power range 0.55 to 400kW) and the W23 Sync+ IE5 series permanent magnet synchronous motors (power range 0.75 to 1250kW), which can seamlessly replace traditional IE3 motors. This series of products has achieved a significant reduction in energy loss through optimized electromagnetic design, selected magnetic materials and precise manufacturing processes.

Dual advantages of energy saving and efficiency

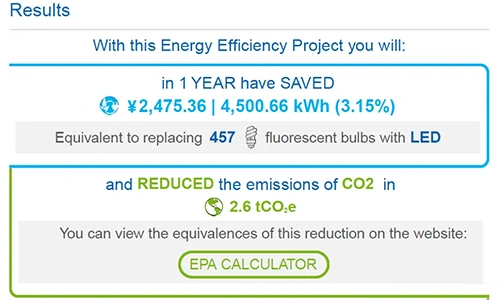

The ultra-high energy efficiency of IE5 motors is its core advantage. Compared with traditional IE3 motors, the losses of IE5 motors are reduced by about 40%. Taking a 15kW 4P motor with an efficiency of 92.1% as an example, after replacing the IE5 motor (efficiency 95.1%), the annual power saving can exceed 4500kWh and the carbon dioxide emissions can be reduced by 2.6 tCO2e, bringing significant economic benefits to the enterprise. and environmental benefits.

Technological innovation, excellent performance

The research and development of IE5 motors embodies the challenges and breakthroughs of engineers to the limits of technology, as well as huge R&D investment. Its electrical and cooling design is extreme, the dimensional accuracy is strictly controlled, and advanced copper casting rotor technology is used on some machine bases. During the manufacturing process, IE5 motors use precision production processes and strict quality control systems to ensure that each motor can meet the highest performance standards. Through advanced CNC technology and automated production lines, production efficiency is improved, waste generation is reduced, product quality is improved, and the foundation for the sustainable development of the enterprise is laid.

Easy maintenance and extended life

The exquisite craftsmanship and high-quality materials of IE5 motors enable low operating temperature rise, low wear, low failure rate, and reduced maintenance requirements. The optional WEG Scan intelligent monitoring system can realize real-time monitoring and fault warning of the motor’s operating status, effectively avoid downtime losses, and extend the service life of the motor.

Environmental protection first, help carbon neutrality

Against the background of global climate change and increasingly urgent environmental protection, IE5 motors have become an important force in promoting the realization of carbon neutrality goals in the industrial field with their ultra-low energy consumption and near-zero emissions. For example, in a system with more than 2,000 geared motors installed, each running 16 hours a day, when using a standard IE3 asynchronous motor compared to the corresponding IE5 motor, the latter can save about 400 kWh of electricity per year and reduce carbon dioxide emissions by about 0.15 tons (carbon emission coefficient 366g/kWh). Such a system can reduce carbon dioxide emissions by 300 tons per year while saving a lot of electricity.

Policy support, broad market prospects

With the global emphasis on energy efficiency improvement and environmental protection, governments have introduced policies to encourage the research and development and application of high-efficiency motors. As the pinnacle of energy efficiency levels to date, IE5 motors naturally become the focus of policy support. Tax incentives, subsidy policies, priority procurement and other incentives provide strong support for the market promotion of IE5 motors.

In summary, IE5 motors, with their technical, process-oriented, energy-saving and low-carbon advantages, have become a key force in promoting industrial green transformation. The strength of WEG and the wide application of IE5 motors indicate that future industrial production will be more efficient, environmentally friendly and sustainable. Let us join hands with WEG to welcome a greener and better future.