1. Core Specification Requirements for Fire Pumps

The selection of fire pump types should be comprehensively determined by integrating multiple factors, such as the reliability of the fire water supply system, installation site conditions, fire water source characteristics, designed flow rate, and required head. To ensure stable operation, fire pumps are preferably equipped with direct drive systems, which can be powered by either electric motors or diesel engines. It is important to note that dual-motor or dual-power drive configurations based on diesel engines are not allowed for fire pumps.

A complete set of fire pumps for a single fire water supply system usually consists of one working pump and one standby pump to ensure uninterrupted operation in case of emergencies. For a single fire pump, the minimum rated flow rate shall not be less than 10 L/s, and the maximum rated flow rate shall not exceed 32 L/s. Manufacturers of fire pumps are required to provide complete flow-head performance curves, which should clearly mark key parameters including flow rate, head, net positive suction head (NPSH), power, and efficiency.

When centrifugal pumps are adopted as fire pumps, the specific model should be selected according to the actual working conditions, such as the required flow rate, head, NPSH, rotational speed, noise level, and environmental requirements of the installation site. In addition, when the actual discharge flow rate of the pump reaches 150% of the designed flow rate, the outlet pressure must not be lower than 65% of the designed pressure to ensure the fire extinguishing effect.

The sealing method and material of the pump shaft must meet the operational requirements of fire pumps under low-flow conditions to prevent leakage. All fire pumps in the same pump group should be of the same model, and the number of pumps operating simultaneously shall not exceed three. For the main components of the pump, the pump casing is preferably made of ductile iron, while the impeller is preferably made of bronze or stainless steel for corrosion resistance and durability.

For diesel-powered fire pumps, compression-ignition diesel engines must be used, and the supporting battery should be able to ensure the automatic start of the fire pump at any time. The capacity of the fuel tank for diesel-powered fire pumps should be determined based on the expected fire duration, with a minimum effective volume of 1.5 liters per kilowatt (L/kW), and the remaining fuel in the tank shall not be less than 5% of the total capacity.

Axial-flow deep well pumps are mainly installed on fire water sources such as water wells and fire water tanks to meet the water supply needs of deep water sources. Pressure-stabilizing pumps are preferably single-suction single-stage or single-suction multi-stage centrifugal pumps, and the main components such as the pump casing and impeller are preferably made of stainless steel to extend service life. The designed flow rate of the pressure-stabilizing pump should not be less than the normal leakage rate of the fire water supply pipeline network and the automatic start-up flow rate of the system; generally, it is calculated as 1% to 3% of the designed flow rate of the fire water supply, and shall not be less than 1 L/s.

2. Classification of Fire Pumps

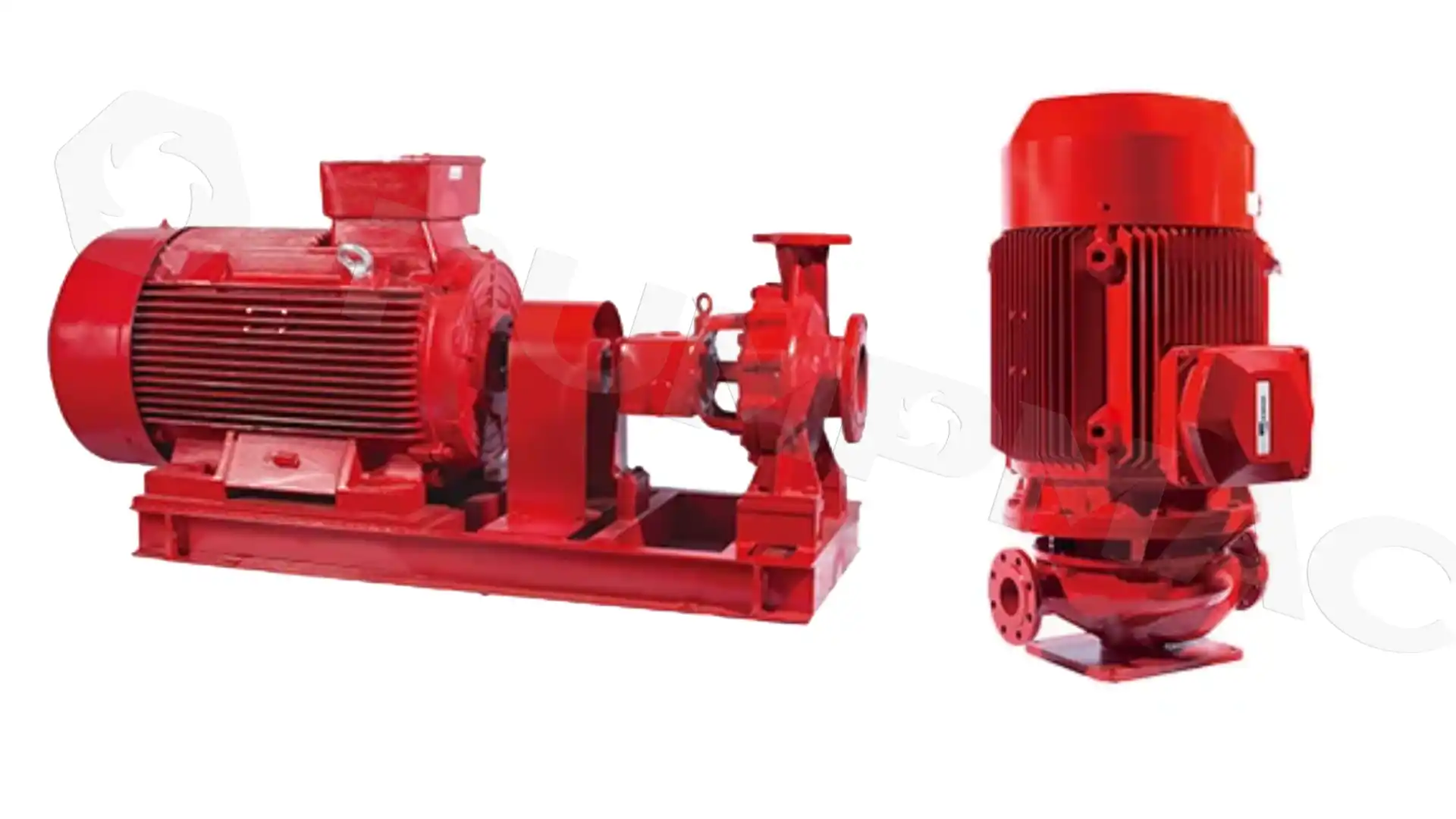

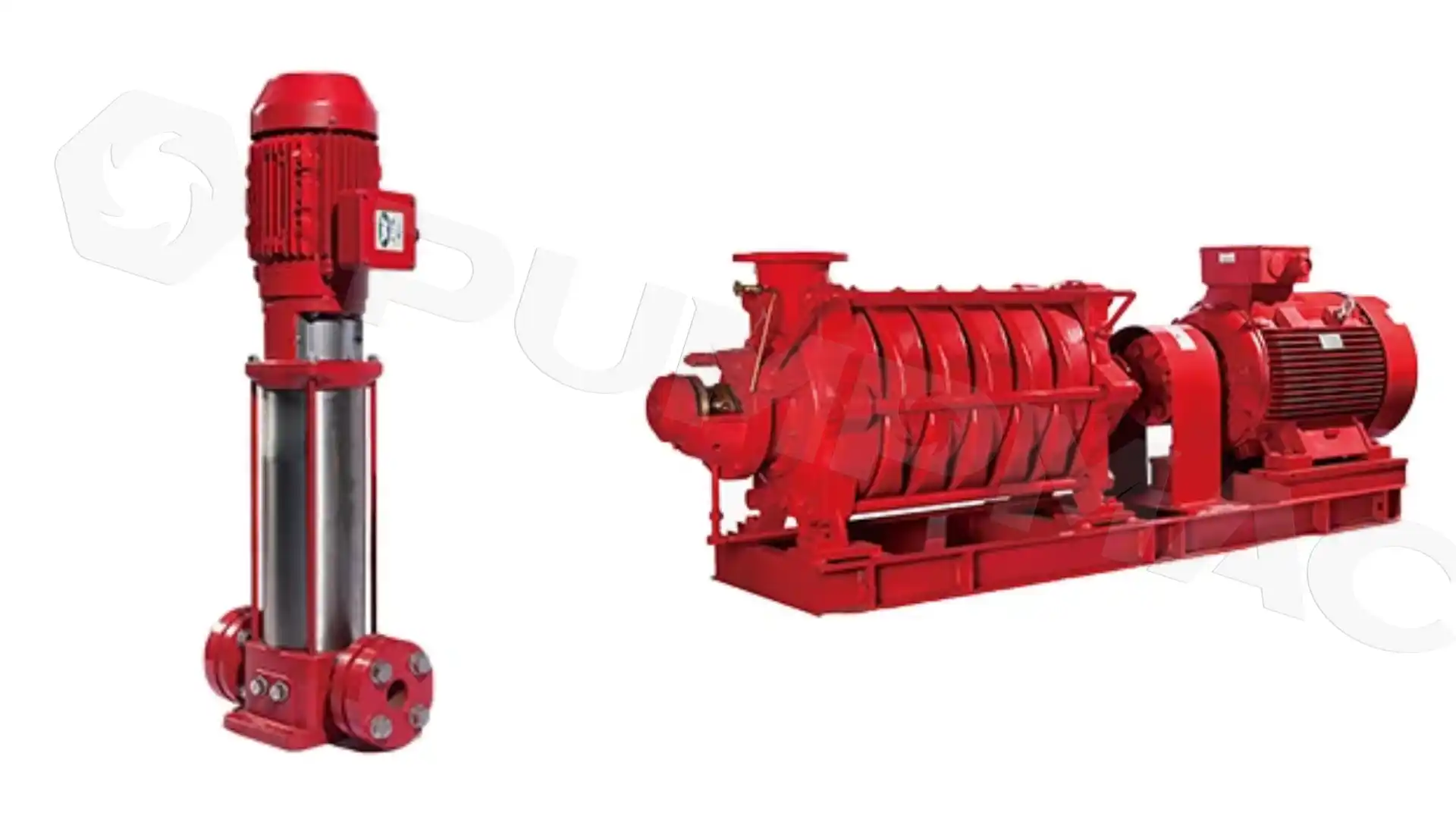

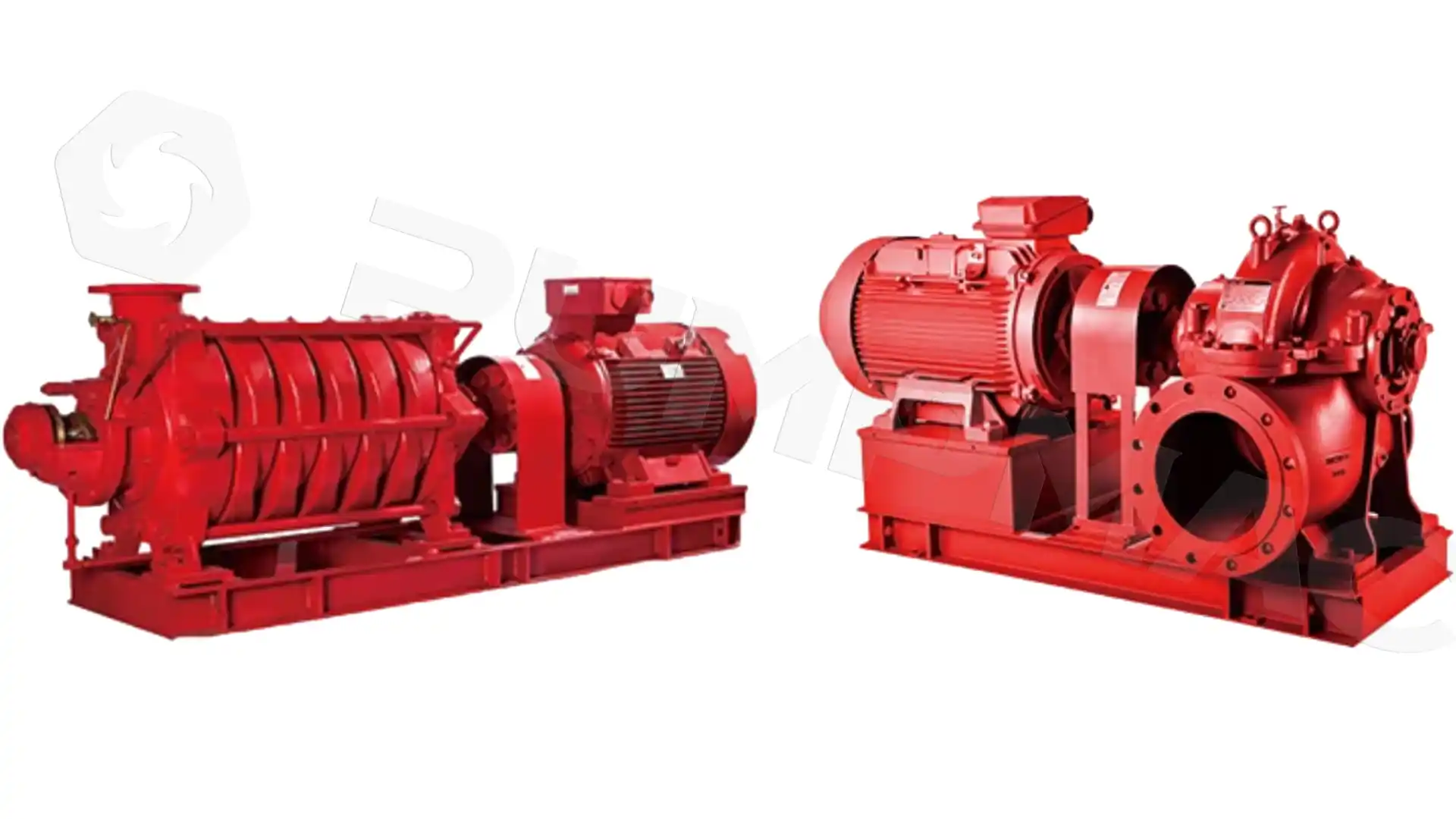

Classified by Structural Form

Single-stage pump: This type of pump is equipped with only one impeller, which is suitable for fire water supply systems that require high flow rate but low head.

Multi-stage pump: Equipped with two or more impellers, it is specially designed for high-pressure and high-head fire water supply scenarios, such as high-rise buildings.

Vertical pump: The pump shaft is installed perpendicular to the ground, featuring a small footprint and being suitable for installation in confined spaces with limited area.

Horizontal pump: The pump shaft is installed horizontally, which requires a larger floor space and is more suitable for open installation areas without space restrictions.

Classified by Drive Method

– Electric motor-driven fire pump: A fire pump powered by an electric motor, which is widely used due to its stable operation and low maintenance cost.

– Diesel engine-driven fire pump: A fire pump powered by a diesel engine, which is suitable for scenarios where the power supply is unstable or interrupted, ensuring emergency water supply.

– Dual-power fire pump: Equipped with two or more power sources (usually electric motor and diesel engine), it can switch power sources automatically to ensure continuous operation.

Classified by Working Principle

– Positive displacement pump: It transports fluid through the periodic change of the volume of the pump chamber, which is suitable for special fire water supply scenarios with high pressure and small flow rate.

– Long-shaft pump: A special type of fire pump designed for deep well water supply, which can effectively extract water from deep wells to meet fire extinguishing needs.

3. Pump Head of Fire Pumps

For fire-fighting centrifugal pumps, the pump head specifically refers to the pressure head, which represents the energy obtained by a unit weight of fluid after passing through the pump. The value of the pump head is closely related to the structural design of the pump, such as the diameter of the impeller, the curvature of the blades, and the rotational speed of the pump. The larger the impeller diameter and rotational speed, the higher the pump head usually is.

In practical engineering applications, the pump head is not expressed in energy units, but in the form of liquid column height (denoted by H), with the unit of meters (m). This expression method is more intuitive and convenient for engineering calculation and on-site construction.

Simple Estimation Method for Pump Head: In fire engineering, there is a common conversion relationship between pressure and head: 1 MPa = 100 m of liquid column height (i.e., 1 MPa = 10 kPa, and 10 kPa corresponds to 10 m of liquid column height). This conversion relationship can be used to quickly estimate the pump head during on-site inspection and calculation.

4. Pump Flow Rate of Fire Pumps

The pump flow rate (denoted by Q) refers to the volume or weight of liquid transported by the fire pump per unit time, which is one of the core parameters determining the fire extinguishing capacity of the pump. Common units of flow rate include cubic meters per hour (m³/h)

5. Key Considerations for Fire Pump Selection

Vertical height of the building: The vertical height of the building directly determines the minimum required head of the fire pump. The higher the building, the greater the head required to ensure that the water pressure on the top floor meets the fire extinguishing standard.

Pipeline length: The total length of the fire water supply pipeline will affect the pressure loss during water transportation. The longer the pipeline, the greater the pressure loss, so the pump head needs to be appropriately increased to compensate for the loss.

Flow rate requirements: The model of the fire pump should be selected according to the flow rate specified in the fire design standards. Different types of buildings (such as residential buildings, commercial buildings, and industrial workshops) have different requirements for fire water flow rate, which must be strictly followed.

Operating environment: The operating environment of the fire pump (such as ambient temperature, humidity, and corrosiveness) needs to be fully considered. For example, in high-temperature or high-humidity environments, pumps with corrosion-resistant and high-temperature-resistant materials should be selected, and special correction factors should be added to the design parameters to ensure stable operation.

6. Maintenance Points of Fire Pumps

Regular maintenance of fire pumps is crucial to ensure their reliable operation in emergencies. The following are the key maintenance points for fire pumps:

1. Before starting the fire pump, open the air release valve to discharge the air in the pump body and pipeline, so as to avoid air blockage affecting the pump’s start-up and water supply efficiency.

2. Before starting the pump, manually rotate the rotor of the pump to check whether the rotation is smooth and free of jamming. If there is jamming, stop the operation immediately and check for faults such as bearing damage or impeller blockage.

3. Conduct a test start of the fire pump regularly, and check whether the rotation direction of the motor is consistent with the specified direction of the pump. If the rotation direction is reversed, adjust the power connection to avoid damage to the pump.

4. During the operation of the pump, closely monitor the temperature of the pump bearing. The temperature of the bearing shall not be more than 35°C higher than the ambient temperature, and the maximum temperature shall not exceed 75°C to prevent bearing damage due to overheating.

5. Regularly inspect the coupling of the pump to ensure that it is firmly fastened, and check for signs of wear or looseness. If any abnormality is found, repair or replace it in time.

6. If abnormal noises (such as friction, collision, or vibration) occur during the operation of the pump, shut down the pump immediately to investigate the cause, and restart the pump only after the fault is eliminated to avoid further damage.

7. During the operation of the pump, check whether the pump body and the base are firmly fixed to prevent vibration during operation, which may lead to pipeline loosening or pump damage.